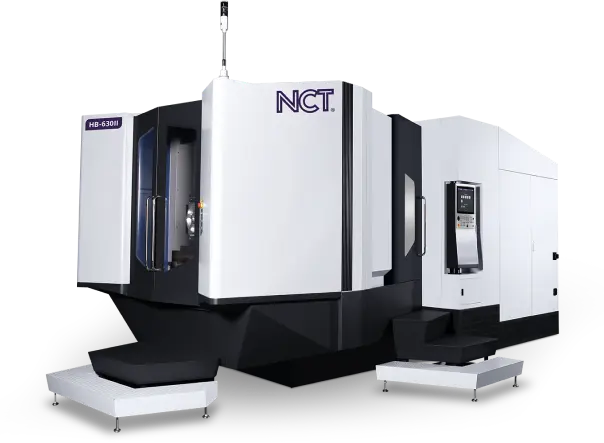

Specifikációk

| ADATOK | |

| FELÉPÍTÉS: | |

| Heavy cast iron bed, column and slides | |

| Semi or fully enclosed spalsh guard | |

| Mounted, precision, roller type (R) bearing linear guideway, on X and Y axes, boxways on Z axis | |

| Slide system, ball screws and bearings with central oil lubrication | |

| Hydraulic counterweight | |

| Telescopic metal guideway cover on every axes heads | |

| ASZTAL: | |

| TORQUE motor driven (DD) Rotary table MILL / TURN function | |

| TORQUE motor driven integrated C axis rotary table (option) | |

| TENGELYEK: | |

| Gearbox driven pretensioned high pitch ball screw on all axis | |

| Cooled ball screws on all axes | |

| GARANCIA ÉS CE: | |

| 36 months warranty for the CNC and for all the electric parts of the machine | |

| 12 months warranty for the mechanical part of the machine | |

| CE conformity | |

| MŰSZAKI SPECIFIKÁCIÓK | |

| FŐORSÓ: | |

| Max.speed (standard) | 6000 RPM |

| Max. speed (option.) | 4000 / 8000 / 10000 RPM |

| Spindle taper size (standard) | #50 |

| Spindle taper size (option) | #40 |

| Tooling | DIN/BT 50 |

| Drive | : |

| Number of ranges | : |

| Headstock cooling | Oilcooler |

| B axis tilting spindle (worm gear transmission) | |

| A and C axis tilting spindle | |

| Continuous tilting movment | |

| Headstock Gearbox (G) or Direct (D) driven | |

| Liquid cooled spindle motor (D type) | |

| Spindle taper #50, DIN or BT tooling | |

| Headstock thermal stabilization with digital oil cooler | |

| SZERSZÁMTÁR: | |

| Magazine type | Karos (opc. láncos) |

| Number of tool positions | 30 / 40 |

| Max. tool length | 400 mm |

| Max. tool diameter | 215 / 125 mm |

| Max. tool weight | 20 kg |

| Tool change time (T to T) | : sec |

| Tool change time (C to C) | : sec |

| Tool change time 180° | : sec |

| Chain type magazine with arm toolchanger, separated from the working space | |

| MUNKATÉR: | |

| 5000 | |

| Table size | 1500 mm |

| Integrated rotary table diameter (option) | mm |

| Max. workpiece size | mm |

| T-slot number x size x distance | 28 x 10 x 200 mm |

| Table load capacity | 17000 kg |

| Spindle nose distance from table surface | 200 ~ 1100 mm |

| Spindle center to Z-axis way cover | : mm |

| Spindle centre distance from column | : mm |

| Distance between columns | 1700 mm |

| TENGELY: | |

| 5 | |

| Number and type of X / Y / Z guideways | : |

| Number and type of X / Y guideways | Roller type |

| Number and type of Z guideways | Box way |

| Number of X / Y / Z block unit | : |

| Number of X / Y / Z block unit | : |

| X travel | 5100 mm |

| Y travel | 2200 mm |

| Z travel | 900 mm |

| W travel | 1 mm |

| A axis | 1 |

| B axis | 1 |

| C axis | |

| Rapid travel speed max. of X / Y / Z axis | 12 / 20 / 15 m/min |

| Max. feed rate | : m/min |

| A / C clamping torque | : mm |

| B / C clamping torque | Nm |

| B axis rated / max. feedrate | RPM |

| C axis rated / max. feedrate | RPM |

| B / C axis indexing resolution | |

| B / C transmission ratio | |

| B transmission ratio | |

| PONTOSSÁG: | |

| X, Y, Z axis positioning accuracy | < 0,04 mm |

| X, Y, Z axis repeatability accuracy | < 0,03 mm |

| A / C indexing accuracy | "/sec |

| A / C axis repeatability accuracy | "/sec |

| B / C indexing accuracy | "/sec |

| B / C axis repeatability accuracy | "/sec |

| FŐMOTOR: | |

| Rated Power (standard) | 22 kW |

| MAX Power (standard) | kW |

| Rated Power (option.) | 30 kW |

| Rated torque (standard) | : Nm |

| MAX torque (standard) | Nm |

| Rated torque (option) | : Nm |

| Cooling | : |

| TELEPÍTÉS: | |

| Floor space x height | 12500 x 5200 x 4380 mm |

| Net machine weight | 43000 kg |

| Power Consumption | 35 kW |

| Electrical connection | 3 x 400 VAC VA |

| Air connection | 6 g/cm2 |

| ALAPTARTOZÉKOK_OPCIÓK | |

| VEZÉRLÉS ÉS ELEKTRONIKA: | |

| Outputs operated by M function | : |

| NCT simulator | : |

| Remote access | : |

| Robot cell junction interface | : |

| NCT 304 smart touch CNC (touchscreen) | |

| EnDat 2.2 absolute measuring system, 0,00005 mm positioning resolution and nano interpolation | |

| Three colour status lamp | : |

| NCT 304 Controller 15" touchscreen | : |

| NCT 304 Controller 19" touchscreen | : |

| Built-in controller | : |

| External, swing-aside control panel | : |

| Built in handwheel | : |

| External handwheel | : |

| HEIDENHAIN Indirect measuring system (absolute) | : |

| HEIDENHAIN Direct measuring system (absolute) | : |

| Spindle and axis motors quadratic acceleration | : |

| HSHP (high speed high precision machining) | : |

| 1 + 1 day training | : |

| Installation and commissioning | : |

| NCT service | : |

| NCT technology telephone helpline | : |

| 19" touchscreen monitor | : |

| NCT 304HS 19" touchscreen monitor | : |

| myNCT graphical programming | : |

| CADCAM softwares | : |

| 1 G Spindle and axes acceleration | : |

| Sending Error messaege via SMS | : |

| Switch off the machine from technological program | : |

| Partial or full installation of axis 4 | : |

| Partial or full installation of axis 5 | : |

| Partial or full installation of axis 4 or 5 | : |

| Green technology | : |

| ALAPTARTOZÉKOK: | |

| B axis tilting head | |

| Arm type, ATC | : |

| Disc type magazine | : |

| Spindle bearing protection by compressed air | : |

| Levelling pads and bolts | : |

| One color alarm lamp | : |

| Light for working area | : |

| LED lights | : |

| Double LED lights | : |

| Chip conveyor and trolley | : |

| Air cooling | : |

| Watergun | : |

| Watergun operated by push button | : |

| Airgun connection | : |

| Machine service rack | : |

| OPCIÓK: | |

| Umbrella type magazine | : |

| Two axis automatic angle head | 1 |

| Cooling Through Spindle | : |

| Semi-enclosed splash guard | : |

| Enclosed splash guard | : |

| Fully enclosed splash guard (enclosed at machine top) | : |

| Increased spindle speed | : |

| Increased spindle power | : |

| Increased spindle torque with motorside gearbox | : |

| Increased spindle torque with headstock gearbox | : |

| Spindle taper #40, | : |

| Increased spindle taper #50 | : |

| One axis automatic angle head | 1 |

| Increased capacity of tool magazine | : |

| Drum type magazine, Arm type, ATC | : |

| Chain type magazine, Arm type, ATC | : |

| Preparation of through tool cooling | : |

| High pressure working space washing apparatus | : |

| Pushbutton working space washing gun | : |

| Oil skimmer | : |

| Coolant filtering with paperfilter | : |

| Chain type chip conveyor | : |

| Spiral, chain or scraper type chip conveyor | : |

| Integrated TORQUE motor driven rotary table (C axis) | |

| CNC rotary / indexing tables, tailstocks and rotating supports | : |

| Increased, longterm accuracy with Heidenhain linear scales | : |

| Increased, longterm accuracy with Heidenhain angle encoder | 1 |

| Workpiece and tool probe preparation | : |

| Workpiece and tool probe | : |

| Workpiece probe (cabled, infrared) | : |

| Workpiece probe (infra) | : |

| Tool probe (cabled, infra) | : |

| Lifting the column | : |

| Drilled plate attachable perforated table | : |

| Outer working space lights | : |

| Hydraulic / pneumatic actuating system for table | : |

| Mist extractor | : |

| Automatic door movement | : |

| SZOLGÁLTATÁSOK: | |

| Delivery, Loading, movement | : |

| Workpiece technologization | : |

| Training at NCT Academy | : |

TEKINTSE MEG TÖBBI GÉPÜNKET IS!

Kérdése van?

Ha bármilyen kérdése, esetleg észrevétele van termékeinkkel vagy szolgáltatásainkkal kapcsolatban, kérjük, keresse munkatársainkat bizalommal!

Keressen minket!