NCT CNC Controllers

Available with 15” and 19” displays

NCT CNC controllers enable precise and efficient operation on CNC machines.

Explore our controllers!

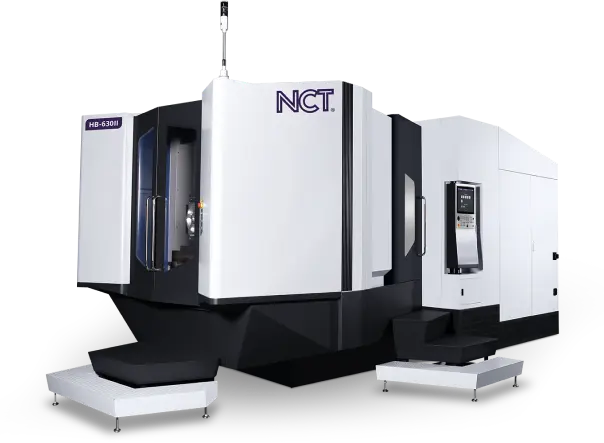

Gear-driven spindle head or direct-drive configuration

Next-generation NCT CNC controllers enable precise and efficient operation in CNC machining tools. With NCT CNC controllers, you can easily program using conversational programming, CAM software, or traditional G-code. In addition, new features help you monitor your machine tool’s proper operation, while consistently high precision and productivity are guaranteed.

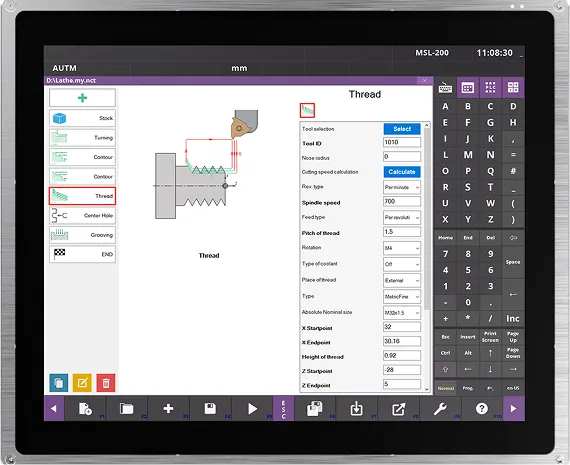

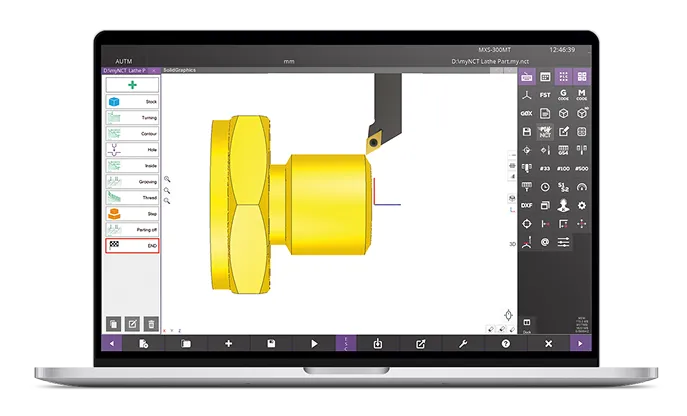

myNCT software is a user-friendly, conversational solution that simplifies and accelerates CNC programming. Its intuitive interface is ideal for both beginners and experienced machine operators, enabling professional results even with minimal experience.

Key features of the myNCT CNC programming software:

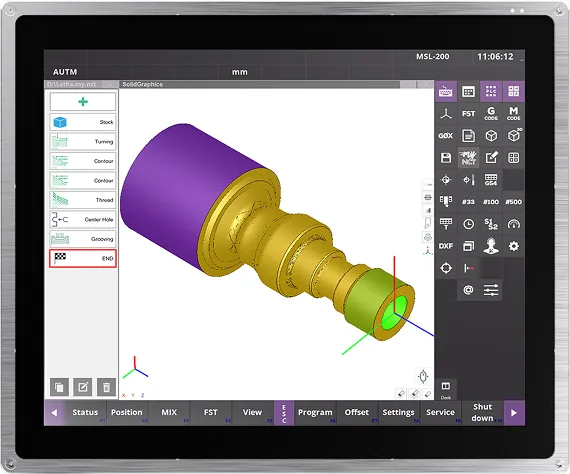

3D solid model graphics in CNC controllers are a breakthrough solution for visual verification of machining processes. This feature helps to:

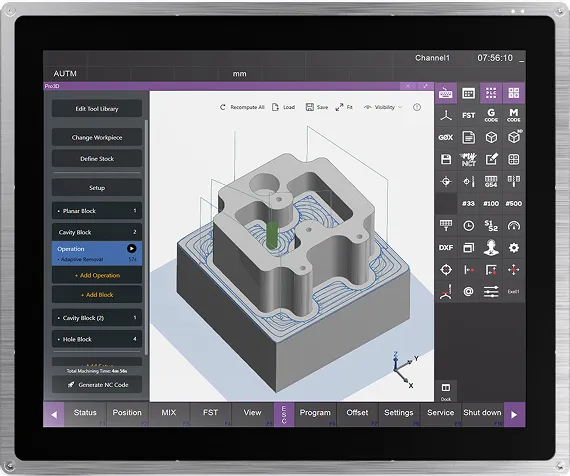

NCT Pro3D software lets you generate a CNC program for milling machines with just a few simple taps. The software provides automatic tool and technology recommendations and can generate toolpaths, so users can create the desired parts without writing complex CNC machining programs.

Learn more about our milling machines!

NCT NOW tracks the operation, downtime, and faults of CNC machine tools in real time, boosting productivity and reducing costs. It supports remote access and energy consumption analysis, enabling efficient, unattended operation.

Explore our lathes as well!A full-featured control and programming interface, optionally integrated with the machine tool’s PLC program.

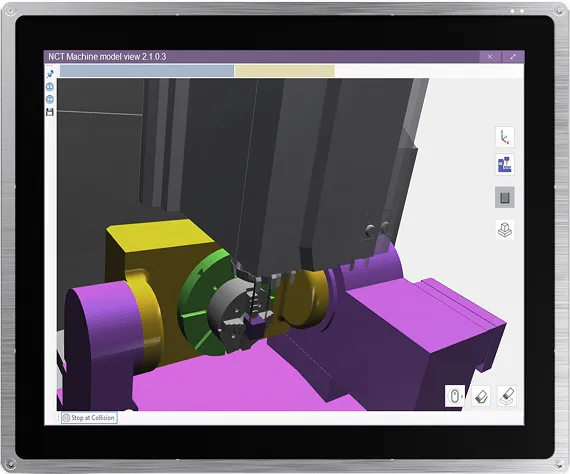

Monitors CNC machine operation in real time and responds immediately to potential collisions. When necessary, it automatically stops or corrects motion to prevent damage. Safer operation, fewer breakdowns, higher efficiency.

The Energy Management Module measures and logs CNC machines’ energy consumption in real time, even broken down by program. It helps optimize production, reduce costs, and accurately track the energy demand of each part.

Contact us

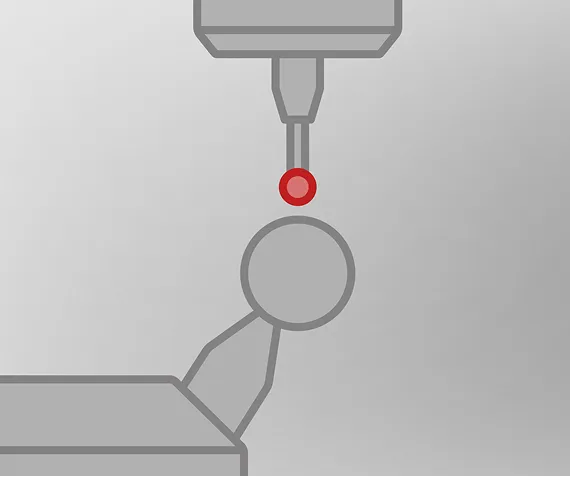

Built-in probing cycles in NCT controllers enable accurate and fast measurement of workpieces directly on the machine. The system automatically detects positions and dimensions, increasing machining accuracy and efficiency.

The rapid development of computer hardware and operating systems has enabled us to create a new type of solution where we were able to integrate the latest WINDOWS operating system for the user interface—without compromises—while preserving the proven, simple hardware architecture of the NCT 201.

The secret lies in the latest quad-core ITX-standard hardware and the brilliant INTime real-time operating system from TenAsys that can be installed under WINDOWS.

In the NCT 204/304 controller, a single computer located behind the screen handles both the CNC and the operator interface (HMI). Inside this one computer, four processors (four cores) are working. Two cores run the well-known WINDOWS operating system with the NCT operator interface (HMI) and a wide range of applications, while the other two cores run the CNC system.

This controller can also run our most modern CNC programming software, VECTOR, and the solid-model visualization integrated into the NCT HMI. We designed the system to be open so that either NCT or the machine builder can replace or further develop the operator interface to match their own needs and the specific machine.

This development opened up a completely new market for NCT. It enabled us to create customized, unique operator interfaces for machine builders. With this, we can reach OEM partners who want to appear in their markets with their own custom-designed CNC operator and programming interface.