NCT CNC Controllers

Available with 15” and 19” displays

NCT CNC controllers enable precise and efficient operation on CNC machines.

Explore our controllers!

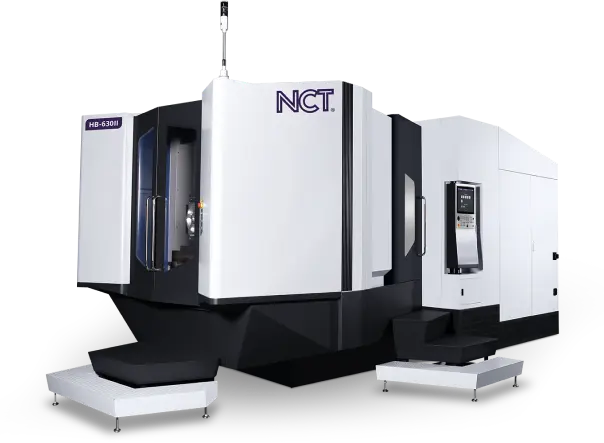

Gear-driven spindle head or direct-drive configuration

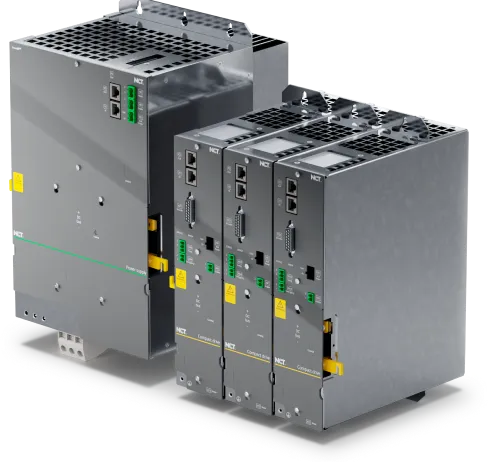

The EtherCAT protocol provides a 1 ms communication cycle time between the controller and the drive, while a 125 µs control cycle time is achieved within the drive itself. The drives are available in a current range from 10 A to 360 A and support synchronous, asynchronous, linear, and torque motors. Integrated feedback interfaces such as EnDat 2.2 and TTL, sine/cosine ensure precise and fast operation, while the system fully leverages the synchronization advantages provided by EtherCAT.

The NCT DSC & DAC compact servo drive family features a space-saving, easy-to-install, and cost-efficient design, as the drive units can be mounted directly next to each other without the need for spacing between modules. The cooling elements of the power transistors can be placed in a ventilated area separated from the electrical cabinet. Automatic cooling fan control ensures energy-efficient operation. Hidden busbars provide an elegant appearance. EtherCAT – standardized (SoE) communication. NCT servo drives also play a key role in NCT’s remote diagnostics services. SoE communication enables remote access down to the level of the EnDat 2.2 encoder mounted on the NCT motor. High-voltage power supply for the drive modules is provided via a recessed busbar system on the front panel. After removing the protective plastic front cover, any individual unit can be removed from the drive assembly by rotating the busbars—without dismantling them.