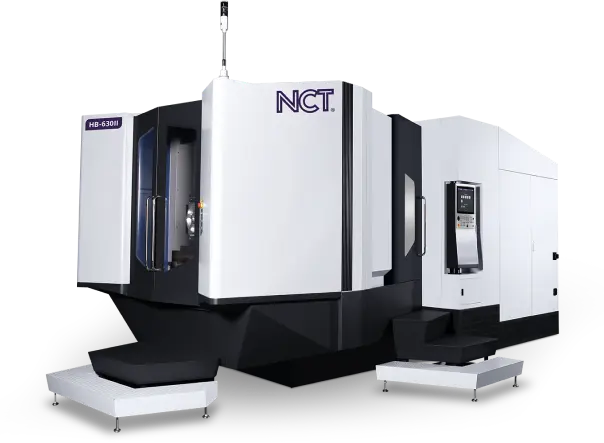

Specifications

| MŰSZAKI SPECIFIKÁCIÓ | |

| Max. swing diameter over bed | 550 mm |

| Max. swing diameter over gap | 770 mm |

| Max. swing diameter over cross slide | 310 mm |

| Max. turning length | 4000 mm |

| Distance between centers | 4000 mm |

| Recommended chuck diameter | 250 / 300 |

| AXIS: | |

| Type of Guideway | Box type guide ways |

| X travel | 300 mm |

| Z travel | 4000 mm |

| X / Z rapid travel speed | 15 mpm |

| SPINDLE: | |

| Spindle nose | A1-8 / D1-8 |

| Spindle bore diameter | 82 mm |

| Spindle bore diameter option | 106 |

| Number of ranges | 2 |

| SPINDLE MOTOR: | |

| Spindle motor power | 11 kW |

| SUBSPINDLE: | |

| TAILSTOCK: | |

| Quill diameter / stroke | 80 / 150 mm |

| Quill / tailstock operation | Manual / Manual |

| Size of internal taper | MT5 |

| TOOLING: | |

| Tool change | Quick Change Tool post / turret |

| Number of tool positions KERESŐ | 4 / 8 / 12 |

| Number of tool positions (optional) | 4 / 8 / 12 pc |

| Tooling | Bolt-on / VDI40 / VDI30 |

| INSTALLATION: | |

| Floor space x height | 6190 x 2245 x 2050 mm |

| Netto machine weight | 6800 kg |

| Electrical connection | 3 × 400 V AC VA |

| ALAPTARTOZÉKOK_OPCIÓK | |

| Machine lights | |

| CONTROL AND ELECTRONICS: | |

| NCT4 Controller 21,5" touchscreen | |

| Built in handwheel | |

| 19" touchscreen | |

| External handwheel | |

| myNCT graphical programming | |

| CADCAM softwares | |

| Three colour status lamp | |

| Green technology | |

| NCT simulator | |

| Remote access | |

| SERVICES: | |

| 1 + 1 day training | |

| Installation and commissioning | |

| NCT customer service | |

| NCT service | |

| NCT technology telephone helpline | |

| Delivery, Loading, movement | |

| Workpiece technologization | |

| Training at NCT Academy | |

| OPTIONS: | |

| Totally enclosed splash guard | |

| Automatic turret | |

| Power operated tailstock | |

| Increased spindle speed | |

| Gyorsváltó késtartó (MULTIFIX) | |

| Servo turret with static tooling | |

| Servo turret with live tooling | |

| Manual chuck | |

| Power operated chuck | |

| Spindle lock with power operated disk brake | |

| Increased spindle positioning accuracy with HEIDENHAIN angle encoders | |

| Enlarged chuck dimension | |

| Power operated chuck with quick jaw change | |

| Tool touch probe (manual or automatic) | |

| Workpiece probe (infra) | |

| Bar puller, bar guide or bar feeder | |

| Cooling Through Spindle | |

| Program controlled coolant pressure | |

| Cooling Through Tool by air | |

| Mist extractor |

Explore our other machines as well!

Do you have any questions?

If you have any questions or comments regarding our products or services, please feel free to contact our colleagues.

Contact us!