Specifications

| ADATOK | |

| CONTROL AND ELECTRONICS: | |

| NCT 304/19" smart touch CNC | |

| Remote control panel | |

| Main spindle braking with regenerative feedback | |

| EnDat 2.2 absolute measuring system, 0.00005 mm positioning resolution, nano interpolation | |

| WARRANTY AND CE: | |

| CE compliance | |

| 36 moths warranty for the CNC and for all the electric parts of the machine | |

| 12-month warranty on machine mechanics |

| MŰSZAKI SPECIFIKÁCIÓK | |

| WORKING AREA: | |

| Max. swing diameter over bed | 710 mm |

| Max. swing diameter over gap | 970 mm |

| Max. swing diameter over cross slide | 370 mm |

| Maximum turning length | 2000 mm |

| Distance between centers | 2000 mm |

| Recommended chuck diameter | 406 |

| AXIS: | |

| Type of Guideway | Box type guide ways |

| X stroke/travel | 425 mm |

| Z stroke/travel | 2150 mm |

| X / Z rapid travel speed | 10 mpm |

| SPINDLE: | |

| Spindle nose | A2-11 |

| Spindle bore diameter | 153 mm |

| Number of ranges | 2 |

| SPINDLE MOTOR: | |

| Spindle motor power | 17 kW |

| SUBSPINDLE: | |

| TAILSTOCK: | |

| Quill diameter / stroke | 125 / 230 mm |

| Quill / tailstock operation | Manual / Manual |

| Tailstock stroke / operation | 1 |

| Size of internal taper | MT6 |

| TOOLING: | |

| Tool change | Quick Change Tool post / turret |

| Number of tool positions KERESŐ | 4 / 8 / 12 |

| Number of tool positions (optional) | 4 / 8 / 12 pc |

| Tooling | Bolt-on / VDI40 / VDI50 |

| INSTALLATION: | |

| Floor space × height | 4900 x 2977 x 2231 mm |

| Net machine weight | 7000 kg |

| Electrical connection | 3 × 400 V AC VA |

| ALAPTARTOZÉKOK ÉS OPCIÓK | |

| Machine lamp | |

| category | 8 |

| CONTROL AND ELECTRONICS: | |

| NCT 304 Controller 19" touchscreen | |

| Remote handwheel | |

| 19" touchscreen | |

| External Handwheel | |

| myNCT graphical programing | |

| CAD-CAM software | |

| Three-color status signal lamp | |

| Green technology | |

| NCT simulator | |

| Remote machine access | |

| SERVICES: | |

| 1+1 days training | |

| Installation and commissioning | |

| NCT customer support | |

| NCT service support | |

| NCT telephone technological support | |

| Machine transport, loading, machine relocation | |

| Workpiece process development | |

| Training and courses (NCT Academy) | |

| OPTIONS: | |

| Totally enclosed splash guard | |

| Automatic turret | |

| Power operated tailstock | |

| Gyorsváltó késtartó (MULTIFIX) | |

| VDI tooling turret | |

| Servo turret with static tooling | |

| Servo turret with live tooling | |

| Spindle lock with power operated disk brake | |

| Increased spindle positioning accuracy with HEIDENHAIN angular encoder | |

| Enlarged chuck dimension | |

| Power operated chuck with quick jaw change | |

| Chain-type chip conveyor | |

| Through-tool coolant | |

| Program-controlled coolant pressure | |

| Oil skimmer | |

| Air gun connection | |

| Mist extractor | |

| Manual chuck | |

| Power operated chuck | |

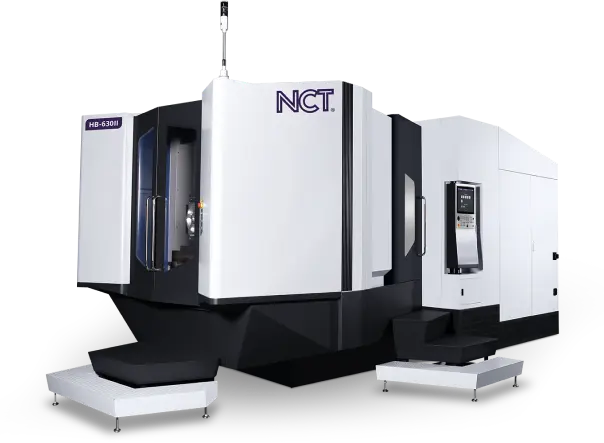

F-TURN-2800A/2000

CNC lathe

Fill out our form and our experts will help you find the most suitable solutions!

-

Flat bed CNC lathe

-

Convenient operation, spacious workspace, wide-opening work door

-

Cast iron bed and slide system

-

Hardened and precision ground box ways, the slide surface coated with TURCITE

-

Direct coupling between servomotor and supported in bearings at both ends

-

Central oil-lubricated slide system and ball screws

-

Motorside gearbox driven spindle

-

Manually or Power operated Chuck

-

Quickchange toolholder, stationary or driven turret

-

Manually or Power operated tailstock

CONSTRUCTION:

AXES:

SPINDLE:

CHUCK:

TOOLING:

TAILSTOCK:

Explore our other machines as well!

Do you have any questions?

If you have any questions or comments regarding our products or services, please feel free to contact our colleagues.

Contact us!