Specifications

| ADATOK | |

| category | 15 |

| MŰSZAKI SPECIFIKÁCIÓK | |

| WORKING AREA: | |

| Table size X | 2700 mm |

| Table size Y | 1050 mm |

| Table load capacity | 6000 kg |

| Positioning accuracy | <0,015 mm |

| Repeatability accuracy | <0,01 mm |

| A IS: | |

| Number of Axis | 3 |

| Number and type of X / Y / Z guideways | Bo ways 2 / 2 / 2 |

| X travel | 2600 mm |

| Y travel | 1000 mm |

| Z travel | 950 mm |

| Rapid travel speed ma . of / Y / Z a is | 10 / 10 / 10 m/min |

| Ma . feed rate | 10 m/min |

| SPINDLE: | |

| Max .speed (standard) | 3500 RPM |

| Spindle taper size (standard) | #50 |

| Tooling | DIN/BT 50 |

| Number of ranges | 2 |

| SPINDLE MOTOR: | |

| Ma . Power (standard) | 17 kW |

| Ma . power (option) | 650 kW |

| TOOL MAGAZINE: | |

| INSTALLATION : | |

| Net machine weight | 13000 kg |

| Electrical consumption | 35 kW |

| Electrical connection | 3 × 400 VAC VA |

| Air connection | 6 kg/cm2 |

| ALAPTARTOZÉKOK & OPCIÓK | |

| STANDARD ACCESSORIES: | |

| Levelling pads and bolts | |

| One color alarm lamp | |

| Light for working area | |

| Coolant system | |

| Watergun operated by push button | |

| CONTROL AND ELECTRONICS: | |

| Three colour status lamp | |

| NCT4 Controller 21,5" touchscreen | |

| Spindle and axis motors quadratic acceleration | |

| HSHP (high speed high precision machining) | |

| 1 + 1 day training | |

| Installation and commissioning | |

| NCT customer service | |

| NCT service | |

| NCT technology telephone helpline | |

| Remote access | |

| CADCAM softwares | |

| Sending Error messaege via SMS | |

| Switch off the machine from technological program | |

| Partial or full installation of axis 4 or 5 | |

| Green technology | |

| Outputs operated by M function | |

| NCT simulator | |

| Robot cell junction interface | |

| OPTIONS: | |

| Drum type magazine, Arm type, ATC | |

| Preparation of through tool cooling | |

| Cooling Through Spindle | |

| Increased spindle speed | |

| Increased spindle power | |

| Spindle taper #40, | |

| Chain type magazine, Arm type, ATC | |

| Oil skimmer | |

| Coolant filtering with paperfilter | |

| Spiral type chip conveyor | |

| CNC rotary / indexing tables, tailstocks and rotating supports | |

| Increased, longterm accuracy with Heidenhain linear scales | |

| Power operated chucks and vises | |

| Workpiece and tool probe preparation | |

| Workpiece probe (cabled, infrared) | |

| Tool probe (cabled, infra) | |

| Hydraulic / pneumatic actuating system for table | |

| Mist extractor | |

| BT tooling | |

| SERVICES: | |

| Delivery, Loading, movement | |

| Workpiece technologization | |

| Training at NCT Academy |

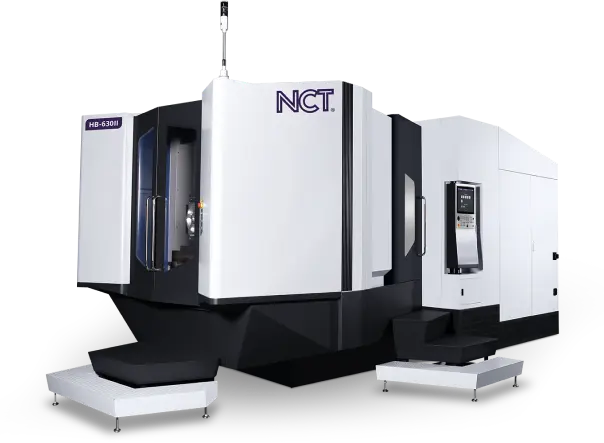

FBE-2600

CNC milling machines

Fill out our form and our experts will help you find the most suitable solutions!

-

Automatikus szerszámcsere főorsó függőleges vagy vízszintes állásában szerszámváltótól függően

-

NCT 304 smart touch CNC (touchscreen)

-

EnDat 2.2 absolute measuring system, 0,00005 mm positioning resolution and nano interpolation

-

36 months warranty for the CNC and for all the electric parts of the machine

-

12 months warranty for the mechanical part of the machine

-

CE conformity

CONSTRUCTION:

SPINDLE:

A IS:

MAGAZINE:

CONTROL AND ELECTRONICS:

WARRANTY AND CE:

Explore our other machines as well!

Do you have any questions?

If you have any questions or comments regarding our products or services, please feel free to contact our colleagues.

Contact us!