Specifications

| ADATOK | |

| The main spindle moves in Z direction | |

| The main spindle moves in Z1 direction | |

| The tools move in X1 and Y1 directions | |

| C and Y axis machining with main and counter-spindle using shared tooling | |

| CHUCK: | |

| Integrated, hydraulically actuated collet chuck | |

| Stationary or synchronous main spindle guide bush | |

| TOOLING: | |

| Gang-type stationary tooling for main spindle | |

| Radial live tooling for main spindle | |

| Axial stationary tooling for main spindle | |

| Axial live tooling for main spindle | |

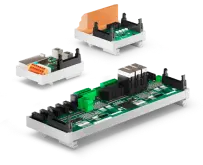

| CONTROLS AND ELECTRONICS | |

| NCT4 touchscreen CNC controller with rotatable control panel | |

| Main spindle braking with regenerative feedback | |

| EnDat 2.2 absolute measuring system, 0.00005 mm positioning resolution, nano interpolation | |

| WARRANTY AND CE: | |

| 36-month warranty on all electrical components of the machine | |

| 12-month warranty on machine mechanics | |

| CE compliance |

| MŰSZAKI SPECIFIKÁCIÓ | |

| WORKING AREA: | |

| Maximum turning diameter | 42 mm |

| Maximum turning length | 220 / 200 mm |

| Remaining material with fixed / synchronized guide bushing | 200 / 200 mm |

| MAIN SPINDLE: | |

| Main spindle bar capacity | 42 mm |

| Guide bushing type | 1 |

| Main motor power | 7.5 kW |

| SUB SPINDLE: | |

| Construction | Single spindle |

| TOOLING: | |

| Drilling capacity with fixed tools | 13 / 10 |

| Tapping capacity with fixed tools | M10 / M8 |

| Number / size of external tool holders (MS) | 6 / 16 x 16 x 95-155 |

| Number / size of fixed boring tool holders (MS & SS) | 5 / ER20 |

| Number / size of driven axial tool stations (MS & SS) | 3 - 3 |

| Driven axial tool max. speed / torque (MS) | 4000 / 4 rpm / Nm |

| Number / size of driven radial tool stations (MS) | 4 / 5 x ER16 |

| Driven radial tool speed / torque (MS) | 3000 / … rpm / Nm |

| AXES: | |

| Number of axis | 4 |

| Rapid traverse rate | 18 mpm |

| INSTALLATION: | |

| Floor space × height | 1 mm |

| Net machine weight | 1 kg |

| Electrical connection | 3 x 400 VA |

| ALAPTARTOZÉKOK_OPCIÓK | |

| STANDARD EQUIPMENT: | |

| Parting tool | |

| Fixed guide bushing | |

| Insert for machining without guide bushing | |

| Hydraulically operated chuck | |

| C-axis machining | |

| Y-axis machining | |

| Leveling feet and bolts | |

| Machine lamp | |

| Push-button coolant washing gun | |

| Coolant tank | |

| Workpiece catcher and discharge conveyor | |

| Tool and toolholder box | |

| CONTROL AND ELECTRONICS: | |

| NCT4 controller with touchscreen | |

| Built-in, swivel control panel | |

| Remote handwheel | |

| Second-stage rapid traverse for spindle and axes | |

| Increased spindle positioning accuracy with HEIDENHAIN angular encoder | |

| Three-color status signal lamp | |

| SERVICES: | |

| 1+1 days training | |

| Installation and commissioning | |

| NCT customer support | |

| NCT service support | |

| NCT telephone technological support | |

| Machine shutdown from technological program | |

| Machine transport, loading, machine relocation | |

| Workpiece process development | |

| Training and courses (NCT Academy) | |

| HS CODE | 8458-1940 |

| OPTIONS: | |

| Driven axial tooling unit | |

| Synchronous guide bushing | |

| Workpiece catcher through sub-spindle | |

| Workpiece catcher for long parts | |

| Coolant chiller unit | |

| Chain-type chip conveyor | |

| Bi-directional fixed tool holder | |

| ER collet set for tools | |

| Clamping and guide collet | |

| Through-tool coolant | |

| Program-controlled coolant pressure | |

| Through-tool air cooling | |

| Tool inspection or measuring probe (infrared) | |

| Bar puller, bar guide or bar feeder | |

| Anti-vibration unit | |

| Mist extractor | |

| CONTROL AND ELECTRONICS: | |

| CAD-CAM software | |

| Error message sending via SMS | |

| Green technology | |

| M-function controlled outputs | |

| NCT simulator | |

| Remote machine access | |

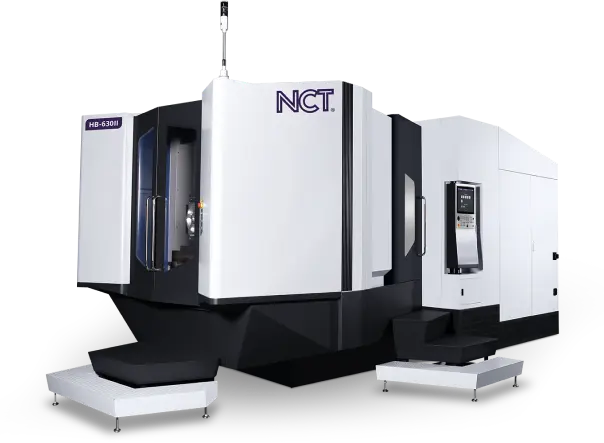

JSL-42A Swiss type CNC lathe

JSL-42A Swiss type CNC lathe

Fill out our form and our experts will help you find the most suitable solutions!

-

Cast iron bed and slide system

-

Mounted, precision linear ball guideways on all axes

-

Guideway protection on all axis ends

-

Ground, high-precision double-nut ball screws

-

Central oil-lubricated slide system and ball screws

-

Convenient operation, spacious workspace, wide-opening work door

-

Built-in motor main spindle drive

-

Belt and intermediate shaft driven synchronous guide bush

CONSTRUCTION:

SPINDLE:

Explore our other machines as well!

Do you have any questions?

If you have any questions or comments regarding our products or services, please feel free to contact our colleagues.

Contact us!