Specifications

| ADATOK | |

| category | 9 |

| CONTROL AND ELECTRONICS: | |

| NCT 304/19" smart touch CNC | |

| Swingaside panel | |

| Spindle deceleration by power back system | |

| EnDat 2.2 absolute measuring system, 0,00005 mm positioning resolution and nano interpolation | |

| WARRANTY AND CE: | |

| 36 moths warranty for the CNC and for all the electric parts of the machine | |

| 12 months warranty for the mechanical part of the machine | |

| CE conformity | |

| MŰSZAKI SPECIFIKÁCIÓ | |

| Max. swing diameter over bed | 900 mm |

| Max. swing diameter over cross slide | 700 mm |

| Max. turning length | 1300 mm |

| Distance between centers | 1300 mm |

| Recommended chuck diameter | 18" |

| AXIS: | |

| Type of Guideway | Box type guide way |

| X travel | 385 mm |

| Z travel | 1500 mm |

| X / Z rapid travel speed | 20 / 20 mpm |

| SPINDLE: | |

| Spindle nose | A2-11 |

| Spindle bore diameter | 155 mm |

| Bar capacity | 117 mm |

| Number of ranges | 2 |

| SPINDLE MOTOR: | |

| Spindle motor power | 30/37 kW |

| Spindle motor torque | 581 / 2160 Nm |

| SUBSPINDLE: | |

| TAILSTOCK: | |

| Quill diameter / stroke | 150 / 150 mm |

| Quill / tailstock operation | Automatic / Automatic |

| Tailstock stroke / operation | 1300 |

| Size of internal taper | MT5 |

| TOOLING: | |

| Tool change | Turret |

| Number of tool positions KERESŐ | 12 |

| Number of tool positions | 12 |

| Tooling | Bolt-on / VDI50/60 / BMT75 |

| Operation | Hydraulic (servo opt.) |

| Number of driven tools (option) | 12 pc |

| Maximum speed of tool | 4000 RPM |

| Maximum power of tool driving motor | 5.5 kW |

| INSTALLATION: | |

| Floor space x height | 5650 × 2350 × 2300 mm |

| Netto machine weight | 13000 kg |

| Electrical connection | 3 x 400 VAC VA |

| ALAPTARTOZÉKOK_OPCIÓK | |

| BOLT-on tooling turret | |

| Power operated three-jaws chuck | |

| Machine lights | |

| CONTROL AND ELECTRONICS: | |

| NCT4 Controller 21,5" touchscreen | |

| External handwheel | |

| Spindle and axis motors quadratic acceleration | |

| 19" touchscreen | |

| myNCT graphical programming | |

| CADCAM softwares | |

| Three colour status lamp | |

| Green technology | |

| NCT simulator | |

| Remote access | |

| SERVICES: | |

| 1 + 1 day training | |

| Installation and commissioning | |

| NCT customer service | |

| NCT service | |

| NCT technology telephone helpline | |

| Delivery, Loading, movement | |

| Workpiece technologization | |

| Training at NCT Academy | |

| OPTIONS: | |

| VDI turret disc with two circles of boreholes | |

| Radial turret with BMT tooling | |

| Servo turret with live tooling | |

| Spindle lock with power operated disk brake | |

| Increased spindle positioning accuracy with HEIDENHAIN angle encoders | |

| Enlarged chuck dimension | |

| Power operated chuck with quick jaw change | |

| Tool touch probe (manual or automatic) | |

| Workpiece probe (infra) | |

| Bar puller, bar guide or bar feeder | |

| Cooling Through Spindle | |

| Program controlled coolant pressure | |

| Cooling Through Tool by air | |

| Mist extractor | |

| Automatic door movement | |

| Robot cell interface |

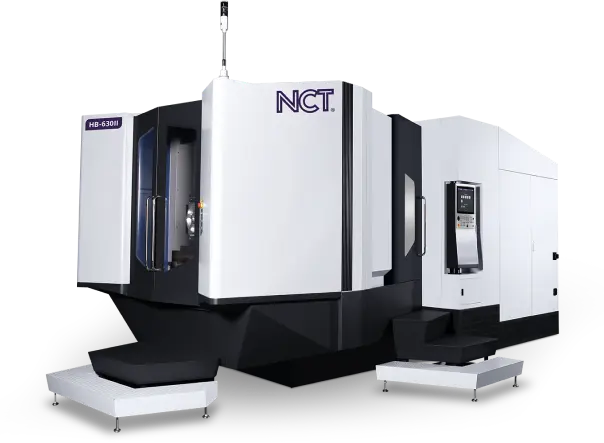

MEGA-117

CNC lathe

Fill out our form and our experts will help you find the most suitable solutions!

-

Real 45° slanted bed, high power CNC lathe

-

Rigid cast iron bed and slide system

-

Hardened and precision ground box ways, the slide surface coated with TURCITE

-

Ground, highprecision double nut ball screws

-

Direct coupling between servomotor and supported in bearings at both ends

-

Slide system and ball screws with central oil lubrication

-

Headstock range switch

-

Power operated chuck or collet chuck

-

Servo turret with axial or radial, static or driven tools

-

Power operated and power positioned tailstock

CONSTRUCTION:

AXES:

SPINDLE:

CHUCK:

TOOLING:

TAILSTOCK:

Explore our other machines as well!

Do you have any questions?

If you have any questions or comments regarding our products or services, please feel free to contact our colleagues.

Contact us!