Specifications

| ADATOK | |

| CONTROL AND ELECTRONICS: | |

| NCT 304/19" smart touch CNC | |

| Main spindle braking with braking resistor | |

| Main spindle braking with regenerative feedback | |

| EnDat 2.2 absolute measuring system, 0.00005 mm positioning resolution, nano interpolation | |

| WARRANTY AND CE: | |

| 36 moths warranty for the CNC and for all the electric parts of the machine | |

| 12-month warranty on machine mechanics | |

| CE compliance |

| MŰSZAKI SPECIFIKÁCIÓK | |

| WORKING AREA: | |

| Max. swing diameter over bed | 5000 mm |

| Maximum turning diameter | 5000 mm |

| Maximum turning length | 2000 mm |

| AXIS: | |

| Type of Guideway | Box type guide way |

| X stroke/travel | 2695 mm |

| Z stroke/travel | 1400 mm |

| X / Z rapid travel speed | 45814 mpm |

| SPINDLE: | |

| Number of ranges | 1 |

| SPINDLE MOTOR: | |

| Spindle motor power | 37*2 kW |

| Spindle motor torque | 68000 Nm |

| SUBSPINDLE: | |

| TAILSTOCK: | |

| TOOLING: | |

| Tool change | Magazin with toolchanger |

| Number of tool positions | 16 pc |

| Tooling | BT50 |

| INSTALLATION: | |

| Floor space × height | 13500 × 9700 × 7600 mm |

| Net machine weight | 82000 kg |

| Electrical connection | 3 × 400 V AC VA |

| ALAPTARTOZÉKOK ÉS OPCIÓK | |

| category | 13 |

| RAM type | |

| Chain chip conveyor | |

| CONTROL AND ELECTRONICS: | |

| NCT 304 Controller 19" touchscreen | |

| 19" touchscreen | |

| SERVICES: | |

| OPTIONS: | |

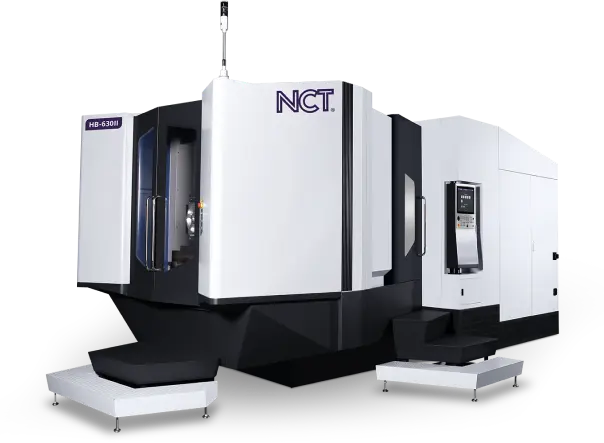

NVL-500RM

RAM type vertical lathe with live tool

Fill out our form and our experts will help you find the most suitable solutions!

-

Vertical bed, Y axis CNC Lathe

-

Spacious working area, wide open working space door

-

Convenient operation, spacious workspace, wide-opening work door

-

Cast iron bed and slide system

-

Rigid cast iron bed and slide system

-

RAM-type design with tool magazine

-

RAM-type design with driven tooling and tool magazine

-

Hardened and precision ground box ways, the slide surface coated with TURCITE

-

Mounted, precision linear ball guideways on all axes

-

Telescopic metal guideway cover on every axis heads

-

Ground, high-precision double-nut ball screws

-

Direct coupling between servomotor and ballscrew by rigid clutch

-

Direct coupling between servomotor and supported in bearings at both ends

-

Central oil-lubricated slide system and ball screws

-

Headstock/spindle bearings with life long grease lubrication

-

Headstock range switch

-

BT50

-

without tailstock

CONSTRUCTION:

AXES:

SPINDLE:

CHUCK:

TOOLING:

TAILSTOCK:

Explore our other machines as well!

Do you have any questions?

If you have any questions or comments regarding our products or services, please feel free to contact our colleagues.

Contact us!