Specifications

| ADATOK | |

| category | 15 |

| MŰSZAKI SPECIFIKÁCIÓK | |

| WORKING AREA: | |

| Table size X | 2000 mm |

| Table size Y | 2500 mm |

| T-slot number size distance | 28 mm |

| Table load capacity | 25000 kg |

| Spindle nose distance from table surface / table center | 1 mm |

| Spindle center to Z-a is way cover | 300-2300 mm |

| Positioning accuracy | < 0,02 mm |

| Repeatability accuracy | < 0,012 mm |

| A IS: | |

| Number of Axis | 5 |

| Number and type of X / Y / Z guideways | Linear |

| X travel | 3000 mm |

| Y travel | 2000 mm |

| Z travel | 2000 mm |

| V löket | 1000 |

| W travel | 800 mm |

| B a is | 360° ° |

| Rapid travel speed ma . of / Y / Z a is | 8 m/min |

| Ma . feed rate | 8 m/min |

| SPINDLE: | |

| Max .speed (standard) | 2500 RPM |

| Spindle taper size (standard) | #50 / 130 |

| Tooling | BT50 |

| SPINDLE MOTOR: | |

| Ma . Power (standard) | 37 kW |

| Ma . torque (standard) | 3374 Nm |

| TOOL MAGAZINE: | |

| Ma . tool weight | 3 kg |

| Tool change time (T to T) | 3 sec |

| INSTALLATION : | |

| Net machine weight | 55000 kg |

| Electrical consumption | 90 kW |

| Electrical connection | 3 × 400 V AC VA |

| Air connection | 6 kg/cm2 |

| ALAPTARTOZÉKOK & OPCIÓK | |

| STANDARD ACCESSORIES: | |

| Spindle bearing protection by compressed air | |

| CONTROL AND ELECTRONICS: | |

| NCT4 Controller 21,5" touchscreen | |

| 1 + 1 day training | |

| myNCT | |

| NCT simulator | |

| OPTIONS: | |

| Semi-enclosed splash guard | |

| Chain type magazine, Arm type, ATC | |

| Chain type chip conveyor | |

| Workpiece and tool probe preparation | |

| SERVICES: | |

| Delivery, Loading, movement | |

| Workpiece technologization | |

| Training at NCT Academy |

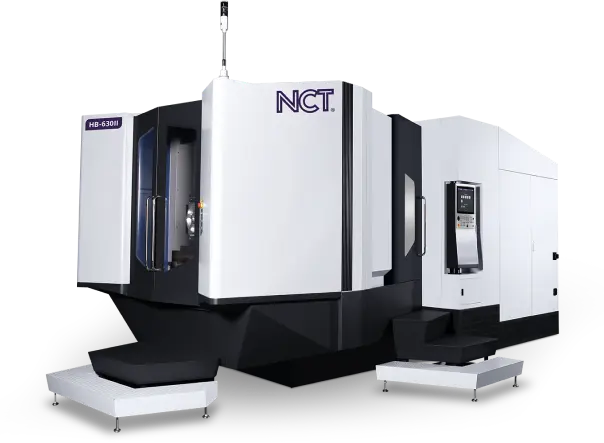

HBM-130CR

Horizontal CNC borring machine

Fill out our form and our experts will help you find the most suitable solutions!

-

Rigid casting bed, column and slides

-

Heavy cast iron bed, column and slides

-

Hydraulic counterweight

-

Telescopic metal guideway cover on every axes heads

-

Headstock Gearbo (G)

-

Spindle taper #50, DIN or BT tooling

-

Spindle Taper cleaning by airblow

-

Ground, highprecision double nut ball screws

-

Ball screws pretensioned and supported in bearings at both ends

-

NCT 304 smart touch CNC (touchscreen)

-

EnDat 2.2 absolute measuring system, 0,00005 mm positioning resolution and nano interpolation

-

36 months warranty for the CNC and for all the electric parts of the machine

-

12 months warranty for the mechanical part of the machine

-

CE conformity

CONSTRUCTION:

SPINDLE:

A IS:

MAGAZINE:

CONTROL AND ELECTRONICS:

WARRANTY AND CE:

Explore our other machines as well!

Do you have any questions?

If you have any questions or comments regarding our products or services, please feel free to contact our colleagues.

Contact us!